Engineering services and pipeline integrity facilities

Engineering services and pipeline integrity facilities

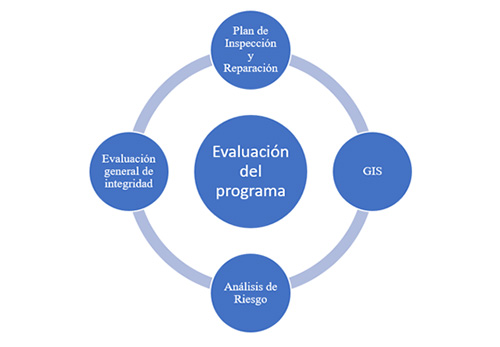

We are a company that provides engineering services, focused on the integrity of facilities. We offer a global analysis of the aptitude for service, advice and technical assistance for the execution of studies and works, analysis and processing of large volumes of information.

Our top priority is to take care of the environment and people. We want to help our clients to work under the same modality, optimizing their resources and focusing them on the most risky problems.

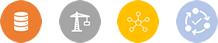

There are detailed technologies to be used and inspection frequencies based on the design conditions of the pipeline, environment, transported product, flow rates, etc.

Customized questionnaires for each client, designed data collection, construction (constructive), operation (operative), etc. Recommendation of practices under national and international guidelines for compliance with the professional standards required by the market.

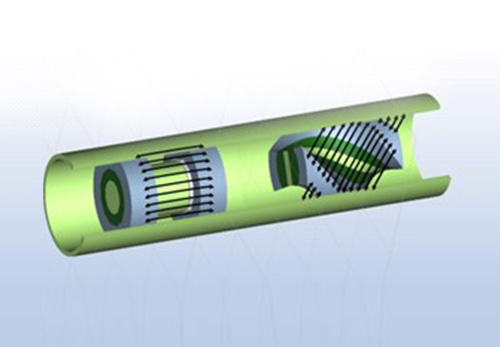

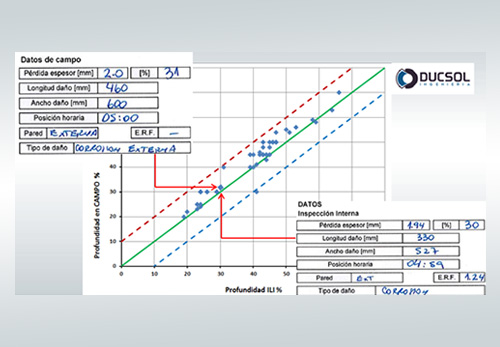

Data crossing based on the technologies of inspection used (methodologies and international practices recommended). Alignment of runs. Historical ILIs analysis. Special studies with raw data information. Fault or safe pressure calculations (PDF).

Maintenance plan detailing the most relevant defects and those recommended to verify/repair as well as the recommended verification methodology and NDT to be carried out. Priorization of defects, according to operating conditions (pressure, temperature, utilization percentage, etc.), location, concentration of defects and other relevant data.

Developed methodology for the validation of the performance of the inspection tool using local regulations and internationally recommended practices.

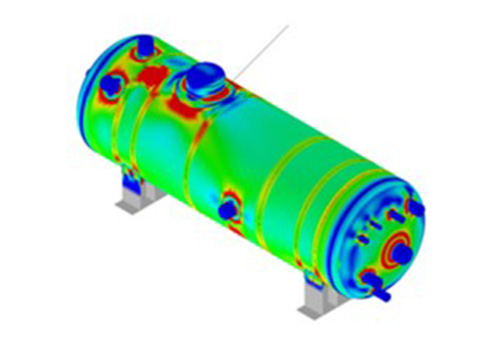

Through National and International Regulations, recommended methodologies of FEM (finite elements) and calculation of safe operating pressure. It is estimated the aptitude to continue in service or to determine new operational windows to safely coexist with defects. New inspection deadlines.

Technical support for companies with transport pipelines or piping systems/pipeline systems.

The failure modes and threats of lines under study are identified according to the operating data, geographic location and environmental conditions. Development of a root cause study of unwanted events.

Ducsol Engineering LLC

8 The Green, Ster in the City of Dover,

Country of Kent, Zip code 19901.

Telephone: +54 9 2314 483495

E-mail: mcardacce@ducsolingenieria.com